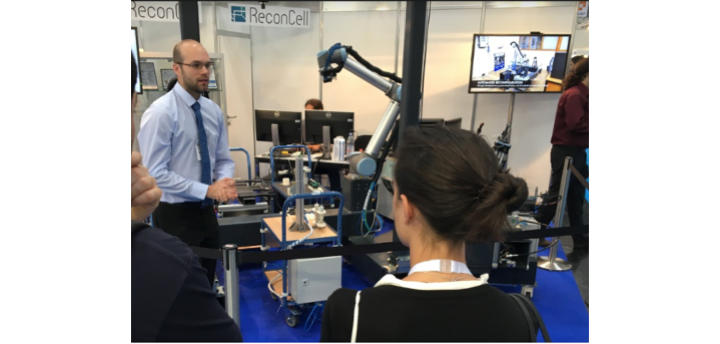

ReconCell grabbed the attention of Industry 4.0 Community at Automatica Trade Fair

From June 19 to 22, 2018, the ReconCell project had the opportunity to present its reconfigurable workcell for fast setup of automated assembly processes at Automatica, the leading Fair for Smart Automation and Robotics in Munich. By demonstrating two of its use cases, visitors could experience the practical usability of the autonomous workcell live. After only 3 years of research and innovation, ReconCell was able to present the autonomous assembly of two different automotive headlights (use case 1) as well as the reconfiguration process to the second use case, the assembly and customization of drive systems and control boxes. The live demo also showed the workcell’s ability for safe human robot collaboration.

Also, in the robot demonstration, ReconCell presented its innovative design of reconfigurable fixtures, which are elementary to create flexibility in autonomous assembly solutions by adopting to any geometrical batch size within seconds. Parts of the workcell were connected through the plug-and-produce interface. It is a practical solution to introduce new workpieces to the autonomous workcell, a key element to foster Artificial Intelligence.

ReconCell was very satisfied with the input from the Industry 4.0 community at Automatica. The feedback enables ReconCell to gain new valuable insights on potential future customers, new use cases and the product roadmap for the ReconCell set up. Based on this, ReconCell is very much looking forward to improving the quality of its existing products and work with recently connected collaboration partners in the future.