Fixture system for workpiece adjustment and clamping with/without its pre-deformation

Main technical issue

The case study is focused on improvement of the productivity and accuracy of large workpiece production through the shortening of the workpiece setup and clamping time. The current situation in the workpiece adjustment is based on extremely time-demanding manual setting, when the operator has to find optimal zero point of the workpiece manually – scribing operation and to fix the workpiece.

Proposed technical solution

The new proposed solution is a comprehensive solution that automates workpiece adjustment and clamping process. It is achieved by the development of:

- Modular active fixtures with centralized control for workpiece leveling. Fixtures allow precise automatic positioning of the workpiece in regards to the machine tool coordinate system. The active fixtures are designed as a compact mechanism that is equipped with a ball screw connected with a servo motor, gearbox and ball nut directly connected with the movable part of the unit. The mechanism is also equipped with linear guideways for better stiffness and a brake located on the linear guideways.

- Modular fixtures for workpiece automatic clamping in adjusted position without deformation and with demanded clamping force. The unit for clamping in additional points consists of two main parts. The first part is an hydraulic work support that can touch the workpiece very slightly and can be fixed in that position. The second part is a swing clamp that can fix the workpiece on the work support by closing the clamping force circuit.

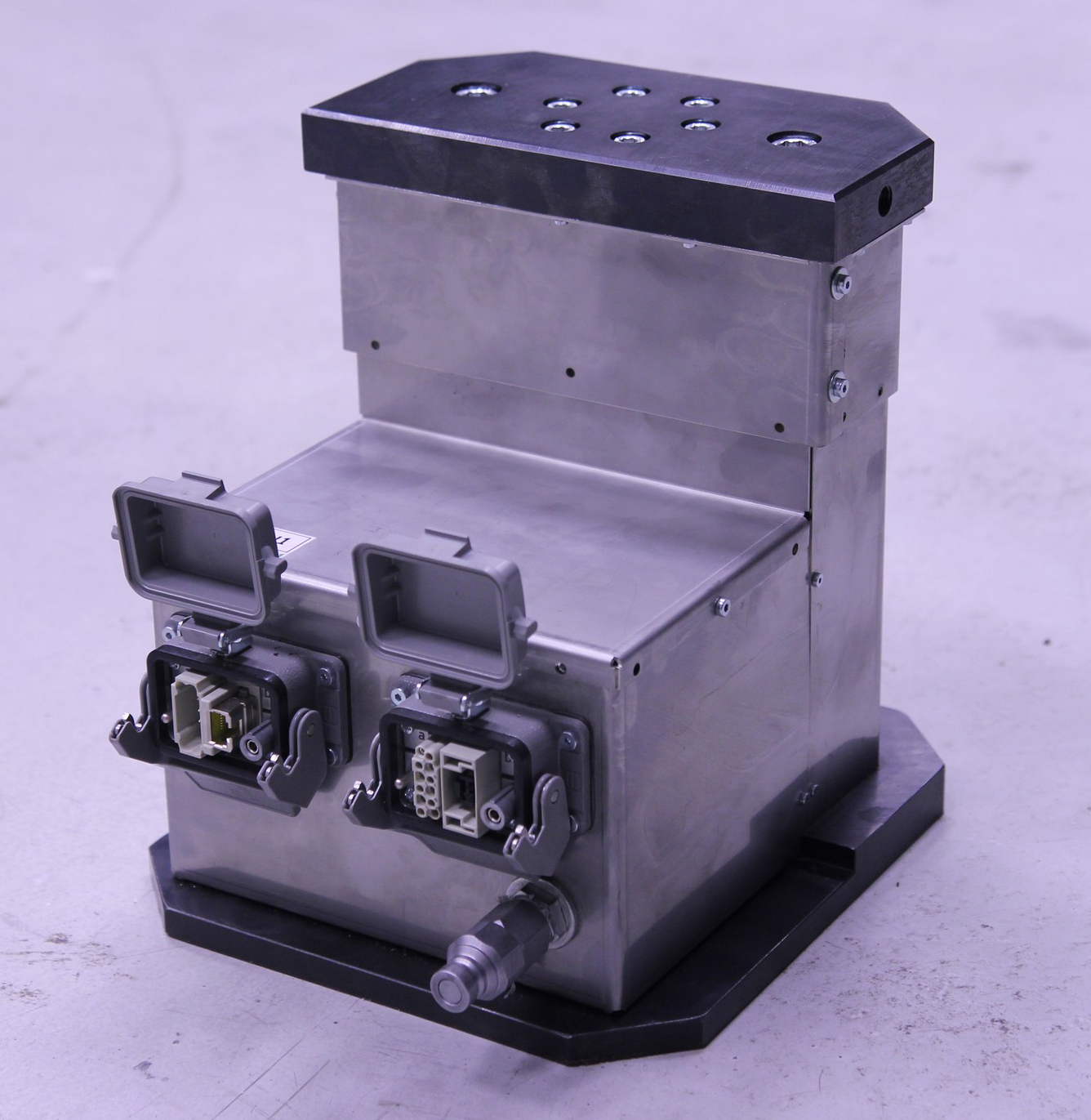

- Active vibration reducer (AVR) as an alternative clamping unit for places where above-mentioned fixtures cannot be used. It is a device composed of one acceleration sensor and one inertial shaker, within an enclosure. This device can be attached to a vibrating structure and it modifies the mechanical impedance of the structure, thus avoiding vibrations.

- Modular fixtures for workpiece automatic clamping and its controlled predeformation, the fixtures is equipped with position and pre-deformation force sensor. The fixture is a combination of the new modular active fixture equipped with a force sensor and clamping part.

- Control system with HMI for above-mentioned fixtures control and cooperation with a machine tool CNC. It consists of the main electrical cabinet with the main control PC (Beckhoff industrial PC) and I/O for control of hydraulic, static fixtures, dynamic fixtures (AVR), an hydraulic circuit, a portable screen with developed software LECLIN and a connection with the machine tool control system.

Main advantages of the solution

The proposed process of levelling and clamping of the demonstration part was performed in approximately 15 minutes, conventional levelling, scribing and clamping operation take about 60 min depending on the operator’s skills. Based on the results, it can be concluded that the automatic workpiece levelling is much faster compared to manual levelling. Position accuracy of the unit is 6 µm with the direct position measurement system. The unit is capable to achieve 5000 N loading force during the movement, stroke 50 mm and, due to the integrated brake, more than 5000 N loading force during machining. (See table page 18) The developed solution can be used for adjusting and clamping different workpieces which makes the solution universal. Despite the fact that the initial investment is relatively high, the proposed leveling and clamping system is costeffective. The key financial benefits are the ability to reduce clamping time significantly and its universal design suitable for different types of workpieces.

Project:

Enterprises:

null

Sector

Other manufacturing

Keywords