Additive Manufacturing – what’s in it for you?

Join the I4MS Community to read more articles like this one

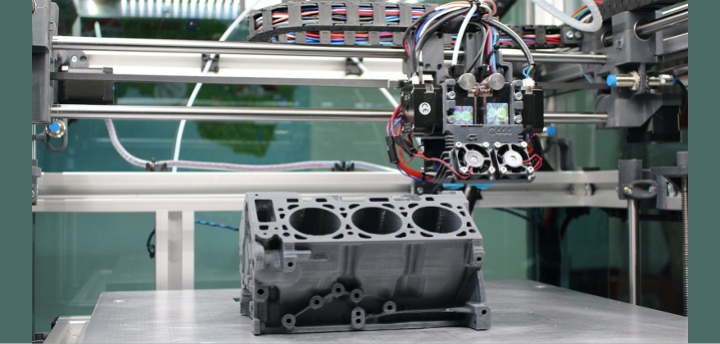

Additive Manufacturing – or the more popular term ‘3D printing’ – is one of our times hot topics regarding new technology in the manufacturing industry. The first 3D printing technique saw the light of day in the early 1980s. For many years the technique was used for rapid prototyping only, but over the last few years, the technology is matured. It has gained ground as a viable industrial production technology due to for instance its precision, quality, repeatability, functional benefits (weight, strength of produced components etc.), production speed, and material range.

The term 3D printing covers many different technologies and a variety of processes in which material is joined or solidified under computer control to create a three-dimensional object, with material being added together, typically layer by layer. One of the key advantages of 3D printing is the ability to produce very complex shapes or geometries.

Olivier Jay from the Danish Technological Institute (DTI), who is an expert within the field of Additive Manufacturing (AM), answers in this article a couple of questions about the technology and how you can start the journey towards introducing AM in your production by means of the Innovation Action AMable.

Can you tell a bit about the development of the technologies behind additive manufacturing?

AM, still quite a new technology in the industry, involves both old and new technologies that constantly evolve, but it has already proven to bring important changes in the manufacturing chain. It started with plastic, but today we can manufacture with 3D printing of other materials as well, for instance metallics. Today, the technology is already used in many sectors, hearing aids, automotive, hifi, space, medical etc.

Even though the AM technology is new within manufacturing, you will probably experience advantages right away. Production on demand, as well as adding the materials has a clear positive impact on the environment, e.g. reduction in materials needed and less waste, but also on the possibility of developing new products as you only need a 3D file for producing new parts. And even if you will experience limitations, as with all new technologies, you will have much more freedom in design, lower weight and shorter production time.

The technology is still at the start of its journey, 3D printing of tomorrow will bring new materials, techniques and functionalities that will permit new commercial advantages.

How far are we in terms of spreading the technology from research to practical, strategic, and commercial use in companies?

Close and far away at the same time. AM is changing the game on many levels of the companies, from selling to producing. Learning how to take advantages from this technology depends on the priorities and requirements of individual companies. In other words, some companies have already implemented an AM production, some use AM for prototyping, and some are not even considering AM as a possible platform for production. You can choose to wait and see what happens or you can follow the first movers, start your own AM journey and gain experience with the technology and find your new unique selling points by exploiting the benefits of 3D printing that will suit your company.

Why should companies apply additive manufacturing in their production?

You will find many arguments for it, but the most important is that at the end of the day, your company will earn more money. Reducing the lead time for new products, better and more customized products, added value through new functionalities or environmental benefits are only a few of the extra advantages. AM is not only used for producing end-products, it is also used for manufacturing robotic components, tools and/or fixtures.

How can companies take advantage of the AMable project?

DTI is part of the EU initiative and I4MS Innovation Action AMable. AMable enables SMEs to take up AM by offering financial support and different AM services. These services are aimed at supporting and upskilling employees in the areas of design for AM, technology development, and business development. AMable is the place to go if you want to see what AM can contribute to in your company. AMable is committed to helping your company with both experiments and assistance from some of the most prominent AM experts around Europe. The important thing is to help you from where you are right now, whether you want to explore if your idea is “AM able”, or you already have an AM production you would like to optimize.

Who can apply for funding through AMable and for what kind of activities?

SMEs and Midcaps are the targets of the AMable project services, but we can also help large companies as the project partners will remain a network of knowledge around AM also in the future. There are different possible activities, initial experiments, or more advanced projects within AMable. The easiest way in is to contact us and we will find the best possible solution for your company. Check out the project website at www.amable.eu for contact information. You can also read more about our services at the Danish Technological Institute here: www.dti.dk/40478.

How many applies for funding and how many receives funding through AMable?

We are accelerating the open calls for funding at the moment, and we expect 2-4 application rounds per year. The number of applications varies from one call to another, but the success rate is between 40-50 %.

The next AMable open call will open in the near future. Stay tuned here:https://i4ms.eu/opencalls.

Jane Hagelskjær, DTI

Join the I4MS Community to read more articles like this one, where you will also find:

– Information about Open calls and funding opportunities for SMEs and mid-caps;

– Access to more than 1000 members of the Industry 4.0 ecosystem;

– Inspiration from other members on the use of I4MS technologies and its benefits;

– News and event about emerging technologies applied to manufacturing.